Smallscale on-site hydrogen generator ideal for use in laboratories, clinics and small factories

Bulk volume hydrogen applications are well known in industry and extensively used on industrial sites and by gas companies, but smallscale hydrogen generators, even down to volumes of only a few cubic centimetres, are rare, uneconomical and expensive.

Filling the obvious void in this specialised field, is a South African company based in Pretoria that specifically imports, installs and maintains small hydrogen generators for on-site application where demand is small.

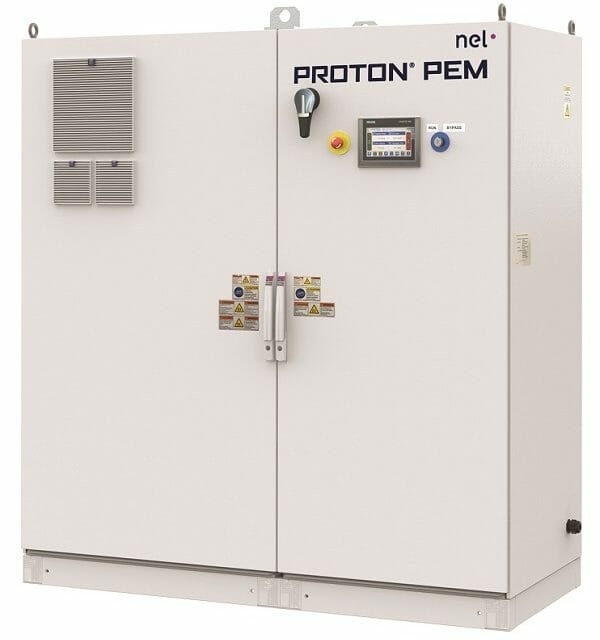

RTS Africa, in collaboration with its long-term Norwegian principal, Nel Hydrogen, has been a leader in the supply of many of southern Africa’s hydrogen electrolyser installations for more than two decades.

With its wide range of industrial uses and applications, hydrogen is a very important molecule. This gas is essential in many sectors such as chemicals, refining, metallurgical applications, glass and electronics manufacturing, food processing and preservation, and in the medical and automotive fields.

“For the supply and storage of hydrogen, small to medium users have relied, for the most part, on gas in cylinders. However, a convenient and consistent means of generating high-purity hydrogen at smaller volumes on site has previously not been readily available,” said RTS Africa Managing Director, Ian Fraser.

“In 2017, Nel Hydrogen bought the US company Proton OnSite, the largest manufacturer of on-site hydrogen generators, which offers its advanced Proton Exchange Membrane (PEM) electrolysis technology to various markets focusing on small to medium plants,” said Fraser who recently spent time with the company in the US to become fully conversant with its PEM technology and electrolyser solutions.

“A constraint with conventional alkaline electrolysers is that they only become economical when producing large volumes of hydrogen – in excess of some 60 to 100 normal cubic metres. It is possible to make smaller alkaline electrolysers but, at that scale, they are not economical,” he said.

But a PEM electrolyser is so compact, it can even be deployed anywhere, even in laboratories for on-the-bench hydrogen generation.

Typically, these units would be supplying quantities of a couple of cubic centimetres but the range of electrolysers also offer installations that can produce bigger volumes.

At the core of a PEM electrolyser is the Proton Exchange Membrane which uses electrolysis, similar to the way a car battery works. Only, in the electrolyser water is used instead of lead and acid.

In an electrolyser, water reacts at the anode to form oxygen and positively-charged hydrogen ions (protons). The electrons flow through an external circuit and the hydrogen ions selectively move across the PEM to the cathode. At the cathode, hydrogen ions combine with electrons from the external circuit to form hydrogen gas.

The technology was developed more than fifty years ago in the United States for use in nuclear submarines where a reliable, risk-free supply of clean, consistent-quality hydrogen is essential.

“At RTS Africa, we are very excited to partner with our principal Nel Hydrogen in marketing this versatile new product to southern African industry,” concluded Fraser.